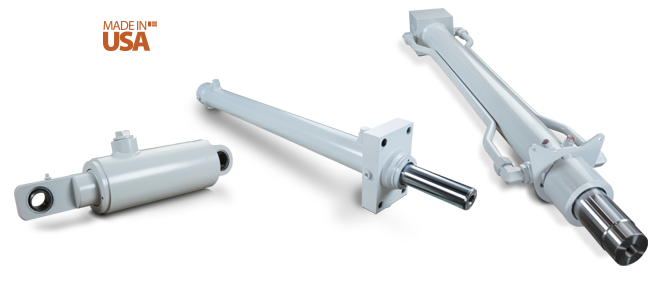

MPH cylinders are designed, manufactured and 100% tested for customer satisfaction. Our cylinders exceed industry standards for material selection and consistency as we select only top tier U.S. traceable material and certified component suppliers, and combine them with our own robust manufacturing processes. Our investment in the latest machining centers, robotic welding, AWS certified welders, and a two-component primer and polyurethane paint system insure the products we deliver will perform in our customers environments.

We combine our technical expertise with nearly four decades of hydraulic cylinder manufacturing experience, and our continued investment in training and technology insure our products deliver on our customers expectations. We provide a range of cylinders with bore sizes 1" to 3 1/2" and 96" maximum stroke (rod sizes 1/2" to 3"), and bore sizes 4" to 8" with 72" maximum stroke (rod sizes up to 4 1/2") with operating pressures up to 5,000 psi.

Our welded cylinders feature hard chrome plating over 85,000 psi alloy-steel with double the industry standard chrome plating...

MoreSnap Ring retention cylinders are produced and make for easy servicing. Cylinders are typically low to medium pressure...

MoreDisplacement Cylinders are produced with a single port and are considered single-acting. Either gravity and weight retract ...

MorePneumatic cylinders can provide several advantages. Some of these include the ability to operate in a clean environment ...

MoreOver the years Mountain Power Hydraulics has done work for a variety of different industries. We have a wide range of diverse applications and are dedicated to making the highest quality products for our always growing number of loyal customers. As a company we will expand and evolve around our customers' needs and wants. Connect with us using the no-obligation form below to begin a conversation about your custom needs.

Our welded cylinders feature hard chrome plating over 85,000 psi alloy-steel with double the industry standard chrome plating thickness. The strength and hardness provide a huge advantage. Each custom engineered single or double-acting cylinder will have properly sized and application specific seal, bearing package to provide a long useful life and minimize downtime. Many standard mounting configurations available or custom configurations can also be designed. Our modular design allows for a virtually unlimited configuration while maintaining industry leading delivery times and availability. Integrated valves, rod and piston cushioning, port type, sizing and locations, and bearing options are just a few of the custom selection options available. Alternatively, if there is an existing design, Mountain Power Hydraulics can duplicate or offer improvements while exceeding the OEM's design requirements.

Displacement Cylinders are produced with a single port and are considered single-acting. Either gravity and weight retract the cylinder or some may be spring assist return. Displacement Cylinders have one advantage to standard cylinders in that they only require the volume of the rod diameter versus the barrel I.D. when extending which gives them a higher rate of travel even with a smaller pump. The rod diameter also determines the extend force rather than the barrel diameter.

Snap Ring retention cylinders are produced and make for easy servicing. Cylinders are typically low to medium pressure.

Pneumatic cylinders can provide several advantages, some of these include the ability to operate in a clean environment such as in proximity to food. Rates of speed can be high as flow of the air from compressors can flow with little resistance through the plumbing and the return can be exhausted directly to the environment. Pneumatics can also provide lighter options where weight is a concern. The drawbacks of pneumatic cylinders and pneumatic circuits can be the compressibility of air may create undesired movements that are not smooth and hydraulics can generate more force for the same size.